Get Tech Tips

Subscribe to free tech tips.

Changing Refrigerants and Why it Matters to You

Graphic Courtesy of Danfoss

On 8/8/17, the United States court of appeals struck down an EPA phaseout of HFC refrigerants under the Clean Air Act on the basis that the Clean Air Act only gave the EPA the right to regulate ozone-depleting substances. However, many of us figured that the decision was likely to be appealed further. As you all know, that decision didn't hold up. The AIM Act of 2020 gave the EPA the green light to phase down HFC refrigerants. Needless to say, the refrigerant landscape has changed since 2017; we need to focus on changing refrigerants as a result.

There are a lot of resources out there that can help HVAC/R professionals adapt to the reduction in HFC refrigerants. Danfoss's Refrigerant Transition Center is a hub of valuable information on global changes to refrigerants and their expected impact on equipment and the industry. AHRI's Safe Refrigerant Transition Task Force has also published many fact sheets, webinars, and other resources that can help contractors as they transition to low-GWP refrigerants. I'd also be foolish not to mention ESCO Group's Low GWP Refrigerant Safety online course, which prepares HVAC/R professionals to work with low-GWP alternatives.

This is a quick overview of the different types of refrigerants, the reasons for the changes, and some things to watch out for.

ODP & GWP

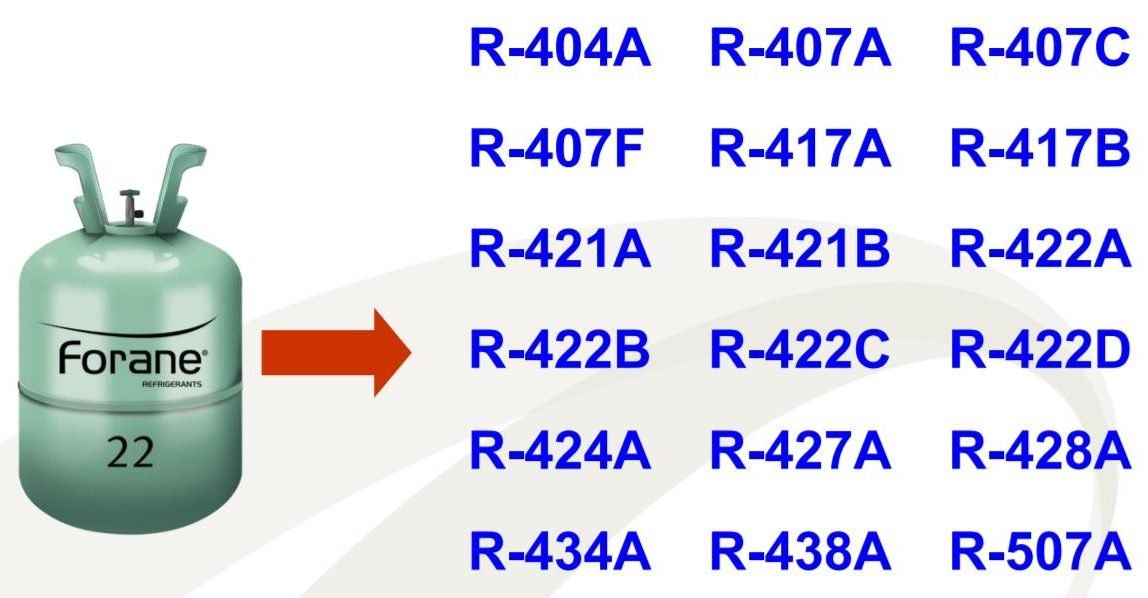

When I went to trade school in the '90s, all the talk about refrigerant regulation stemmed around the destruction of the ozone layer by CFC (Chlorine, Fluorine, Carbon) refrigerants like R-12 and HCFC (Hydrogen, Chlorine, Fluorine, Carbon) refrigerants like R-22. The likelihood that a particular chemical would break down ozone in the stratosphere was designated by an ODP (ozone depletion potential) number. The worst offender was R-11, and it was the benchmark for ODP with a rating of 1. Other refrigerants like R-12 and R-22 had a lower ODP than R-11 but still had the potential for ozone depletion.

Over time, these CFC and HCFC refrigerants have slowly been phased out in the developed world, starting with Europe and moving on to the USA and many other countries.

The attention of the scientific and regulatory world has now shifted to considering the emission of greenhouse gases like methane and carbon. Scientists have studied the effects these gases have on global climate and have concluded that they contribute to global warming.

The term used to identify how much a particular gas contributes to global warming is GWP (Global Warming Potential). The number starts at 1 with carbon dioxide (CO2) and goes up from there with common modern HFC (Hydrogen, Fluorine, Carbon) refrigerants like R-410a and R-404a, which both have zero ODP but high GWP numbers.

Because of this, manufacturers like Danfoss have looked carefully at alternative refrigerants by looking at new technologies and some refrigerants that have been around for a very long time.

Hydrocarbons

The hydrocarbon category contains FANTASTIC refrigerants with excellent heat transfer, pressure/temperature, and oil miscibility. The only problem is they are all flammable. These include R-290 (Propane), R-600a (Isobutane), R-1270 (Propylene), and even some uses of butane and ethane in refrigerant blends. These refrigerants are already being used in some small self-contained units like soda machines and water fountains. They have zero ODP and very low GWP.

Naturals

Natural refrigerants were the earliest refrigerants used. People started using air and water and then moved on to ammonia and carbon dioxide. All of these refrigerants are inexpensive with little to no GWP, and they all can be used as refrigerants.

Water and air have never been economically viable when compared to other refrigerants based on the power input to BTU output.

Carbon dioxide has a low critical point, making it fairly well-suited for colder climates and low-temperature equipment. However, it poses some challenges in areas with higher outdoor temperatures.

Ammonia is arguably the best refrigerant available, but it is highly corrosive and toxic, making it a real safety risk.

HFO (Hydrofluoroolefins)

HFO refrigerants have a similar makeup to HFCs, but they break down more quickly, greatly reducing their chances of making it to the upper atmosphere. Currently, R-1234YF is a commercially available HFO that is a replacement for R-134a (HFC) in refrigeration and automotive applications. R-454B (branded by Chemours as Opteon™ XL41) is also emerging as a replacement in A/C systems; Carrier has opted to use R-454B in its newly manufactured ducted systems and rooftop units.

Recent Changes

As stated in another article on HVAC School, the HFC phasedown was slated to start in 2022. Unlike the R-22 phaseout, R-410A production is not coming to a full stop. We're only seeing a relatively small reduction in production, 10%. However, the plan is to reach an 85% reduction by 2036.

Many of the high-GWP HFC replacements fall under ASHRAE's A2L class; they are non-toxic but can propagate flame under certain conditions. HFOs like R-1234yf and R-454B are A2L refrigerants, as is R-32. So, we will need to keep that in mind when working on systems with A2L refrigerants and replacing systems. Due to the differences in ASHRAE flammability categories, retrofitting current R-410A systems is not possible. We'll also have to make sure our tools, especially recovery machines and vacuum pumps, are suitable for A2L refrigerants.

If you want to learn more about recent refrigerant changes, check out our podcast with Jason Obrzut from ESCO. Jason is a co-author of the RACT manual and is on AHRI's Safe Refrigerant Transition Task Force. You can listen to it HERE or watch the video below.

Comments

To leave a comment, you need to log in.

Log In