Get Tech Tips

Subscribe to free tech tips.

Better Temperature Measurements

I am in the midst of testing the accuracy and repeatability of different types of airflow measurements for techs in search of the most practical methods for different applications.

A commonly taught method for measuring airflow is the temperature rise method, where you use a heat source that produces a set number of BTU/h, such as heat strips. Then, using the sensible heat air equation, you can “easily” calculate the CFM being produced by the equipment. Let's use this specific example to illustrate the challenges in getting a truly reliable measurement.

The typical equation used for a fan coil with electric heat is:

CFM = (Volts x Amps x 3.41) / (1.08 x Delta T)

- Measured heat strip volts x amps will give you the watts (This will generally be a reasonably accurate measurement, depending on the meter's accuracy.)

- 3.41 is a constant watt-to-BTU conversion

- The 1.08 is a combination of factors 1 CFM x 60 minutes per hour = 60 CFH x 0.075 pounds per cubic foot (standard air) = 4.5 x 0.24 Specific heat of air = 1.08

- The delta T is only as accurate as the thermometer used and its placement in the air stream

The first bit of trouble comes in when you realize that almost no air is “standard air,” which is 70°, 0% RH air at sea level. That leaves us with a 0.075 lbs per cubic foot standard air number, which isn't very accurate at all. To see how far off it can be, try messing with the air density calculator on our calculator page.

In the case of my test, I found that a 1.05 multiplier was more accurate than 1.08, based on my indoor air conditions during the test.

Before the test, I used a TEC TrueFlow meter to confirm the actual system airflow. The system was a 2-ton Carrier FV ECM air handler, and both the fan charts and the TrueFlow confirmed a system airflow of 700 & 718 CFM, respectively.

I turned on the 5KW electric heat and ran the system with electric heat only for 5 minutes. Then, I calculated the BTU/h of the heat strips at 12,158. I took a delta T between the return riser and the supply plenum 24″ above the fan coil with the same pocket thermometer. The delta T was fairly stable at 1°.

It doesn't take a math major to figure out that a 1° delta T = WAY MORE AIRFLOW THAN 718 CFM

12,158/1 x 1.05 = 12,766 CFM

So, what went wrong?

In this particular case, we realized that the evaporator coil was still at a lower temperature than the return air, and there was still moisture on the coil and in the drain pan because it had been running in cooling mode before, which was decreasing the temperature of the air inside the air handler. Once the system ran in heat mode for another 15-20 minutes, the delta T came up to 6°.

Still WAY too low!

12,158/(6 x 1.05) = 1,930 CFM

Next, I moved the thermometer to the side, and I was getting a 10° delta T. Then, I moved it to the back, and all of a sudden, I was reading a 17° delta T, which was putting us right in the range, a little low actually (681 CFM). With the pocket thermometer, we saw an 11° variation depending on where I placed the probe!

So, why was this occurring? Even at 24″ above the air handler, the air had not fully mixed, and there were defined areas of high temperature and low-temperature air in the supply plenum.

I gave up on the pocket thermometer and used a longer Testo probe and a K-type bead probe to get closer to the center of the air stream. I then took three measurements—one in the front, one on the left side, and one in the back. Then, I added them together and divided that number by 3. That gave an average of the supply air temperature from multiple points, and the result was a calculation of 755 CFM, which is still on the high side but definitely a usable figure.

I then tried it at different blower settings to see if this new averaging method worked under different airflow conditions. Sure enough, it was within 10% of the factory fan charts and the TrueFlow.

Out of curiosity, I ran the system in cooling mode to see if I would get a similar level of variation. While I did see a difference, it was only 2° due to the mixing in the blower after the coil.

Those of you who work on gas furnaces with coils on top know how much the supply air temperature measurement can vary based on where you place your probe due to poor air mixing and radiant cooling near the coil. That is the same effect I saw above the heat strips.

Here are some good rules for accurate measurement in critical test circumstances:

- Probe placement matters. When possible, take readings 6′ away from the appliance and out of “line of sight” from the cooling/heating surface (heat strips, heat exchanger, coil).

- Use the same probe to take the return and supply readings to improve accuracy if the device isn't highly accurate (more than +/- 1°).

- The speed of the reading matters; a K-type bead is not the most accurate measurement, but the quick read they give will help reduce the impact of radiant heat on the probe if you are within “line of sight” of the heat source.

- When performing any temperature rise calculation, the entire inside of the appliance must be the same temperature as the return air and completely dry.

- When a temperature measurement is critical, it is best to take multiple measurements and average them vs. trusting a single measurement.

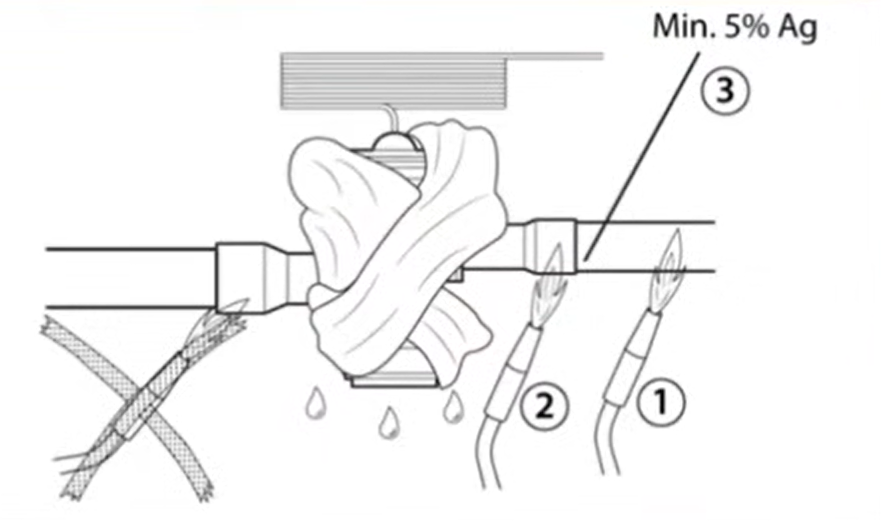

In this case, we are looking for an accurate differential temperature; the absolute values don't matter as much. I found that the quick read and insertion depth of a K-type bead probe (shown below) was a good tool for this measurement, even though it doesn't give the MOST accurate reading.

On another note…

I also neglected to add extra BTUs of heat to the equation to compensate for what is added by the blower if we wanted to get really crazy.

Motor heat added is:

Volts x amps = watts

Watts x (1 – efficiency) = watts of heat added

Watts x 3.412 = BTU of heat added

Just in case you wondered.

—Bryan

Comments

Bryan, Nice blog. Paul Francisco (Northwestern) did a lot of testing on this and published a paper, I think. If you know Paul, you might reach out to him. If not, I’ll see if I can get a copy.

Bryan, Nice blog. Paul Francisco (Northwestern) did a lot of testing on this and published a paper, I think. If you know Paul, you might reach out to him. If not, I’ll see if I can get a copy.

To leave a comment, you need to log in.

Log In