Get Tech Tips

Subscribe to free tech tips.

Axial, Radial, and Digital Scrolls

Courtesy of Copeland

The design goal of most modern compressors is to make them more efficient and better able to match loads, hopefully without reducing ruggedness. The Copeland Scroll Digital™ or digital scroll is one compressor design that has become very popular due to its simplicity and versatility.

But before we go further, let's define some terms.

For years, I've heard about “axial and radial compliance” from Copeland, so let's define those quickly.

Axial

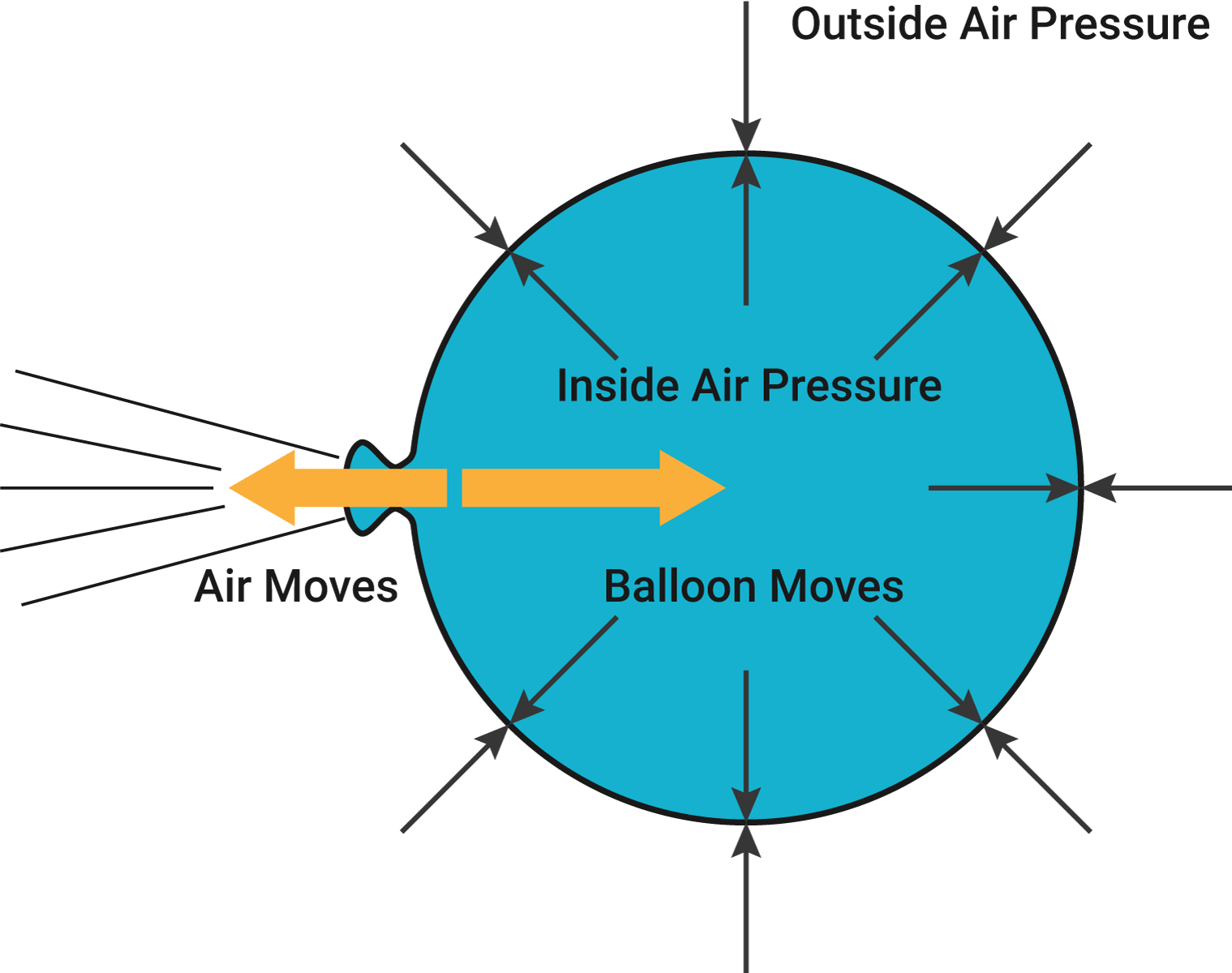

These are the forces in line with the axis or center of the scroll; they're the “up and down” forces that hold the stationary top plate together with the oscillating bottom plate.

Radial

These are the forces in line with the radius of the scroll plates; they're the “side-to-side” forces that keep the two plates in contact with one another.

Compliance

Here is Copeland's definition of compliance:

“Compliance” is the ability to separate under abnormal conditions.

In other words, the scroll plates are forced together top to bottom (axial) and side to side (radial), but if something goes wrong, they can separate to help prevent damage. I show how that works a little bit in the video below.

A Copeland digital scroll uses the axial (up and down) compliance to intentionally load (full capacity) and unload the compressor on and off for various periods of time. This feature helps match compressor capacity to the equipment load.

Courtesy of Copeland

These digital scrolls have a solenoid that allows fully-loaded operation as usual when it's de-energized and allows for fully unloaded operation when energized. By varying the ratio of loaded time to unloaded time, the compressor can vary its output over a period of time and provide excellent capacity control. Technicians in the field may hear this loading and unloading and think that something is going wrong because it does sound quite unusual to the untrained ear.

My brother was working on a large rooftop unit and heard it unloading, so he brought out his ammeter. He observed a consistent increase and decrease in compressor amperage. Sure enough, it was a Copeland digital scroll.

—Bryan

Comments

To leave a comment, you need to log in.

Log In