Get Tech Tips

Subscribe to free tech tips.

Aftermarket Motor Selection & Considerations

This article was written by technician and HVAC School community star Kenneth Casebier. Thanks, Kenneth!

When looking at replacing a single-phase A/C motor with an aftermarket motor from your van, there are a few things you should know and pay attention to.

First, the factory OEM motor will always be the best option, especially when replacing blower motors in a furnace or fan coil unit. That motor was specifically designed for the static pressure and application of the unit. Sometimes, that isn’t always an option. For those times, there are a few guidelines that will aid in ensuring that the motor of choice will be a good decision for both the tech and the consumer.

The first hard, fast rule when selecting a motor is going to be frame and size. The frame of the motor needs to match the application; the last thing you want to do is modify a piece of equipment just to install a motor that may fail because of improper installation. Then, the equipment may not accommodate the right motor because of the modifications made. The actual depth of a condenser fan motor is very important, as an aftermarket motor may have a taller body than the original and can create a situation where the blade won't be positioned properly in the cabinet/shroud, leading to incorrect amounts of airflow and potentially causing issues with obtaining the correct amp draws for reliable performance. Blade position can be EXTREMELY important to condenser airflow and should be carefully considered, especially when up-sizing the HP of a motor.

The next most important consideration is amps. The amp draws need to be similar to the factory motor. Always check the data plate, as the motor you’re removing may have been changed with an improperly matched motor, thus why you are there now. A good rule to follow is to keep amp draws within +/– 5% of the original—but as close as possible or exact is a best practice. You have to keep in mind that the blade, blower wheel, and ductwork or shroud will affect the ability to load up a motor properly. If you choose a motor too far out of specs for the application, you may find yourself in a potential situation for a prematurely failing motor.

(Note from Bryan: If you are replacing an OEM motor with a more efficient motor, such as replacing a PSC with an ECM, the amperage may go down in those cases and still be acceptable.)

Horsepower is the biggest value that there seems to be some confusion on. An easy way to make a wise choice when selecting an aftermarket motor is NEVER DECREASE HORSEPOWER! Keeping the HP the same or increasing it by no more than one value is a safe practice that will keep you from going back and replacing the motor again.

An example of this would be if you have a failed OEM 1/4 hp motor, a “like” 1/3 hp would be an acceptable option. However, a 1/2 or 3/4 hp motor may work but will likely cause size issues and will be more costly to operate for the end-user. Therefore, it is a bad choice.

The last major consideration when selecting a replacement motor is RPM. In PSC motors, you want the match to be exact. A 1075 RPM PSC motor is a 6-pole motor with a synchronous speed of 1200 RPM, and an 825 RPM motor is an 8-pole motor with a synchronous speed of 900 RPM. Some motor manufacturers will use slightly different RPM ratings, such as 1100 vs. 1075, but this is still a 6-pole motor, and the 1075 can replace the 1100.

Additionally, it is good to look at the bearing type used when replacing; ball bearings have a longer life but are often noisier than sleeve bearings. Also, consider the ambient temperature rating of the motor and choose higher temp rated motors in more extreme ambient conditions where appropriate.

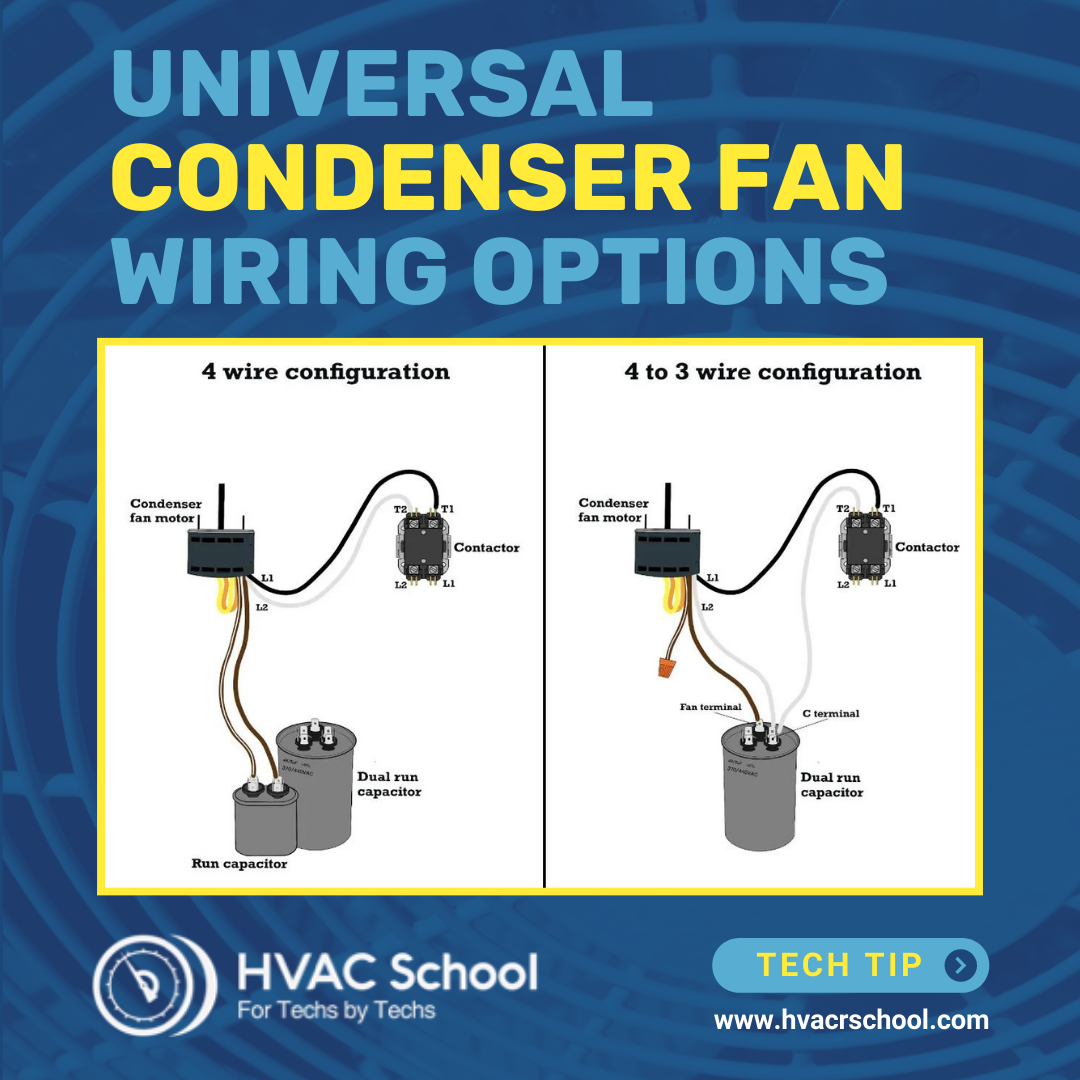

Always use the properly sized capacitor when replacing a motor, and it is a good idea to replace capacitors with motors as a precaution.

Remember, no aftermarket motor will be an “EXACT” replacement, and for that reason, I always recommend the factory OEM when possible. In extreme temperatures, I know getting the equipment operational can be a driving factor in the decision-making process, and I’ve even “loaned” a motor to someone until I could order and return with the OEM. This can incur extra costs to the owner, but it’s still better—and sometimes cheaper—in the long run than leaving an improperly applied motor in a system.

—Kenneth Casebier

P.S. – If you want to learn more about the process of replacing a condensing fan motor, check out this article.

Comments

To leave a comment, you need to log in.

Log In