Get Tech Tips

Subscribe to free tech tips.

Three-Phase Voltage Imbalance

When reading ANY article about electrical theory or application, keep in mind that it will only scratch the topic's surface. You can dedicate years of your life to understanding electrical theory and design the way many engineers do and still know just enough to be dangerous. In HVAC, we rarely need to have a DEEP understanding of electrical design. However, there are a few cases where a little knowledge can go a long way when it comes to identifying issues before they cause trouble, and that is the intent of this short article.

What is Three-Phase Power?

Power is generated at the utility in three phases that are 120 degrees out of phase with one another at 60 Hz (Hertz). That simply means that each individual leg of power makes one peak and valley (a full circle) 60 times per second, and all three of the phases together split the cycle into thirds (trisect).

This video is the best visual demonstration I have seen of three-phase power and how it works.

We also have an article on the basics of three-phase motors, which you can read right HERE.

What Does an HVAC Tech Need to Know About Three-Phase Power?

Three-phase motors don't require a run capacitor because the 120-degree phase difference is ideal for efficiently spinning a motor, so a “start” winding and a phase-shifting capacitor aren't needed.

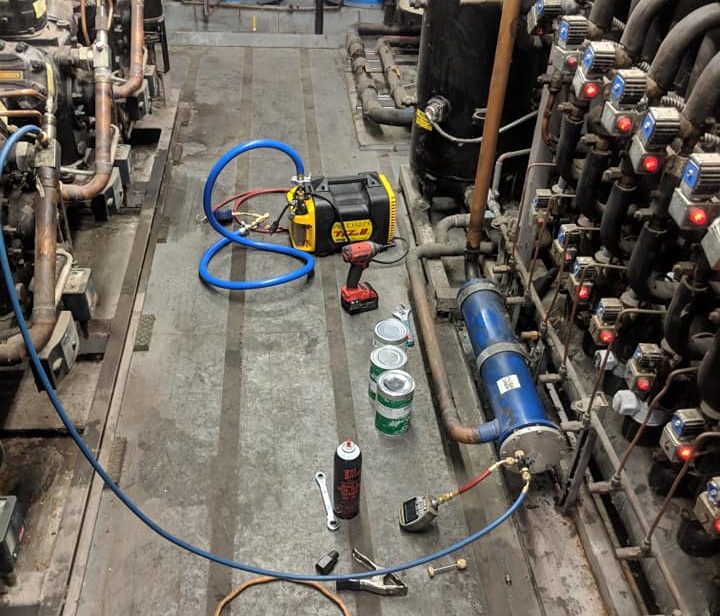

The biggest concern for the techs and installers working with three-phase power is getting the phasing correct so that motors run in the correct direction. While this doesn't matter for reciprocating compressors, it is important for condenser fans and blowers, and it is absolutely CRITICAL for scroll and screw compressors. Changing the direction of rotation is just as simple as swapping any two phases.

When installing replacement parts and equipment, you will generally be in good shape if you keep the phases connected in the same way. It is still a good practice to use a phase rotation indicator—like the one above—to confirm proper rotation. In most cases, clockwise phase rotation is what you are looking for, but I'm sure there are exceptions to that. Alternatively, you can disconnect the compressor that could be damaged by improper phasing and start up the blower to see if it runs in the correct direction before bringing the compressor(s) online. One caveat is that when motors use a VFD (variable frequency drive), the phase rotation will automatically correct, making them an unreliable test in those cases.

Balancing Phases

Electricians are responsible for balancing the amperage of single-phase loads (both 120v single leg and 208v two-leg loads typical on a wye three-phase system) so that the neutral doesn't carry high amperage on the 120v loads and so that the one leg of power doesn't carry significantly more or less load than the other two. As the amperage load on a particular phase goes up, there is more opportunity for voltage drop depending on the size of the load, size of the transformer, service feeding the space, wire size, and connection quality. This can become a challenge when there is a mix of single-phase outlets, 208v appliances, and three-phase equipment. (You can read more about 208v motors HERE.)

Let's say someone connects a bunch of space heaters on phase A, a few smaller HVAC systems between phases A and B, and almost nothing on phase C. If you have a large RTU that uses three phases, then phase C will tend to have less load, therefore higher voltage. In comparison, the load on phases A and B will fluctuate based on when the smaller systems and space heaters go on and off.

This can cause overheating of conductors and damage, but it can also cause voltage imbalance, which is a real cause for concern for an HVAC technician.

Three-Phase Voltage Imbalance

Voltage imbalance is a motor killer. It causes poor motor performance and increases winding heat, which leads to premature failure. In HVAC blowers and compressors, this additional heat ends up in either the refrigerant or the air, which must then be removed, further decreasing efficiency.

To test for three-phase voltage imbalance, always check from phase to phase, not from phase to ground. You simply check the voltage from each of the three phases to one another and find the average (add all three and divide by three). Then, compare the reading furthest from the average and find the percentage of deviation. I know that sounds like a giant pain for most of you, so we made this easy calculator (top right).

The US Department of Energy recommends that the voltage imbalance be no more than 1%, while other industry sources say that up to 4% is acceptable. In general, you will want to make SURE the imbalance is below 4% and work to rectify anything over 1%.

What Can I Do About It?

You want to first look for the obvious. Melted wires, loose terminals or lugs, undersized wires, pitted contacts, poor disconnect fuse contact, etc. Obviously, if you aren't licensed or allowed to open a panel, you won't always be able to rectify the issue fully by yourself, but you can go a long way toward the diagnosis.

When checking voltage, it is generally best to do it with the system running as close to the motor you are checking as possible. This is the actual voltage the motor is “seeing,” and it's what matters to the operation of the motor. You can then test back towards the distribution point. If you see a big increase in voltage as you test back towards the source, you know you found a voltage drop and a cause or contributor to the issue.

You must consider the issues of amperage load imbalance in the panel, utility issues, and service size once all the basics are covered. Most of all, if the imbalance is severe (over 4%), you don't want to leave your motors running, or you risk damage and expensive repairs.

—Bryan

P.S. – We also have an older video showing exactly what was covered in this tech tip:

Comments

There is a trick to making a 3 phase motor “fit” the delivered voltage. Even though all the windings are the same in theory, there can be small differences that can affect operation. Rotating the pahses feeding the motor until you get the most even amp draw among all 3 phases can help. By rotate, I mean move L1to where L2 was, move L2 to where L3 was and move L3 to where L1 was. You are not swapping and changing the direction, but keeping the same direction and rotating where L1 is. The winding arrangement that best fits the delivered voltage will have the most consistent amp draw among all 3 legs.

There is a trick to making a 3 phase motor “fit” the delivered voltage. Even though all the windings are the same in theory, there can be small differences that can affect operation. Rotating the pahses feeding the motor until you get the most even amp draw among all 3 phases can help. By rotate, I mean move L1to where L2 was, move L2 to where L3 was and move L3 to where L1 was. You are not swapping and changing the direction, but keeping the same direction and rotating where L1 is. The winding arrangement that best fits the delivered voltage will have the most consistent amp draw among all 3 legs.

п»їpharmacie en ligne france [url=https://pharmafst.shop/#]Pharmacies en ligne certifiees[/url] pharmacies en ligne certifiГ©es pharmafst.shop

п»їpharmacie en ligne france [url=https://pharmafst.shop/#]Pharmacies en ligne certifiees[/url] pharmacies en ligne certifiГ©es pharmafst.shop

Kamagra Oral Jelly pas cher: kamagra oral jelly – kamagra 100mg prix

Kamagra Oral Jelly pas cher: kamagra oral jelly – kamagra 100mg prix

pharmacie en ligne fiable: Pharmacie en ligne France – pharmacie en ligne france pas cher pharmafst.com

pharmacie en ligne fiable: Pharmacie en ligne France – pharmacie en ligne france pas cher pharmafst.com

Cialis sans ordonnance pas cher: cialis sans ordonnance – cialis prix tadalmed.shop

Cialis sans ordonnance pas cher: cialis sans ordonnance – cialis prix tadalmed.shop

Kamagra Oral Jelly pas cher: achat kamagra – kamagra 100mg prix

Kamagra Oral Jelly pas cher: achat kamagra – kamagra 100mg prix

Tadalafil 20 mg prix sans ordonnance: Tadalafil achat en ligne – Acheter Cialis 20 mg pas cher tadalmed.shop

Tadalafil 20 mg prix sans ordonnance: Tadalafil achat en ligne – Acheter Cialis 20 mg pas cher tadalmed.shop

olympe: olympe casino cresus – casino olympe

olympe: olympe casino cresus – casino olympe

I’m really impressed along with your writing talents as well as with the structure for your blog. Is this a paid topic or did you customize it your self? Anyway keep up the nice quality writing, it’s uncommon to see a great weblog like this one these days!

I’m really impressed along with your writing talents as well as with the structure for your blog. Is this a paid topic or did you customize it your self? Anyway keep up the nice quality writing, it’s uncommon to see a great weblog like this one these days!

Great video

Great video

Cialis sans ordonnance 24h Cialis sans ordonnance 24h or Acheter Viagra Cialis sans ordonnance

http://clients1.google.ge/url?q=https://tadalmed.com Cialis sans ordonnance pas cher

[url=http://variotecgmbh.de/url?q=https://tadalmed.com]Tadalafil achat en ligne[/url] Acheter Cialis 20 mg pas cher and [url=https://byr.cc/home.php?mod=space&uid=557221]Tadalafil achat en ligne[/url] Cialis sans ordonnance pas cher

Cialis sans ordonnance 24h Cialis sans ordonnance 24h or Acheter Viagra Cialis sans ordonnance

http://clients1.google.ge/url?q=https://tadalmed.com Cialis sans ordonnance pas cher

[url=http://variotecgmbh.de/url?q=https://tadalmed.com]Tadalafil achat en ligne[/url] Acheter Cialis 20 mg pas cher and [url=https://byr.cc/home.php?mod=space&uid=557221]Tadalafil achat en ligne[/url] Cialis sans ordonnance pas cher

To leave a comment, you need to log in.

Log In