BACK

Confirming Liquid Levels with a Little Thermodynamics

Confirming Liquid Levels with a Little Thermodynamics

Léon Creux’s Scroll Design: From Initial Failure to an Enduring Legacy

Léon Creux’s Scroll Design: From Initial Failure to an Enduring Legacy

Traditional & Desiccant Dehumidification and When to Use Each (or Both)

Traditional & Desiccant Dehumidification and When to Use Each (or Both)

Discovering Mental Reference Points

Discovering Mental Reference Points

Three Levels of Acid Testing

Three Levels of Acid Testing

Dedicated Dehumidifier vs. Electric Reheat Dehumidification – Who Ya Got?

Dedicated Dehumidifier vs. Electric Reheat Dehumidification – Who Ya Got?

HH vs. EK Filter-Driers: Technical and Field Comparison

HH vs. EK Filter-Driers: Technical and Field Comparison

3 Ways to Reduce Compression Ratio in a Heat Pump

3 Ways to Reduce Compression Ratio in a Heat Pump

Best Practices to Conserve A2L Refrigerants in a Shortage

Best Practices to Conserve A2L Refrigerants in a Shortage

The Contactor Reimagined w/ Copeland

The Contactor Reimagined w/ Copeland

Capacitor Testing and Replacement – Short #247

Capacitor Testing and Replacement – Short #247

Cold Coil vs. Desiccant Dehumidification

Cold Coil vs. Desiccant Dehumidification

Learning Better – Short #246

Learning Better – Short #246

Intro to The Sigma Capacitor

Intro to The Sigma Capacitor

What’s up with Refrigerant & System Regulations w/ Copeland

What’s up with Refrigerant & System Regulations w/ Copeland

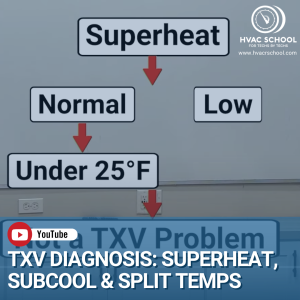

TXV Troubleshooting – Short #245

TXV Troubleshooting – Short #245

Learning and Teaching GRIT w/ Ty Branaman

Learning and Teaching GRIT w/ Ty Branaman

Band-Aids, Hacks, and Ethics – Short #244

Band-Aids, Hacks, and Ethics – Short #244

#hvac

Tech Tips:

Maintaining the correct vapor-liquid refrigerant balance is crucial for air conditioning and refrigeration system performance. Longer line sets hold more refrigerant, which increases the risk of liquid accumulating in the suction line or entering the compressor during off-cycles. Heat pumps are one common application that requires additional measures. Refrigerant flow reverses during heating, turning the […]

Read more

The HVAC/R industry isn’t short on tragic figures. There’s John Gorrie, whose ice machine showed a lot of promise but didn’t have enough financial backing due to the lucrative ice industry and the death of his business partner. While Gorrie may have died without seeing his vision reach the masses, he was ahead of his […]

Read more

This tech tip is based on a conversation with Nikki Krueger and David Schurk. Nikki is a longtime contributor to HVAC School and is a relatively frequent podcast guest and symposium speaker. David Schurk is the Director of Applied Engineering and National Sales Manager at Innovative Air Technologies. Nikki specializes in traditional cold-coil dehumidifiers, and […]

Read more

Trying to wrap your head around HVAC can feel like a constant firehose of new info, right? Whether you're in class or on the job, there's just so much to soak up. And when you finally think you've got one thing down, BAM, here comes another concept. For me, remembering everything can be a real […]

Read more

Anytime we have a compressor failure, we can’t just pull out the bad compressor and drop a new one in. We have to put our detective hats on and find the culprit so that it doesn’t happen again. In many cases, acid is a prime suspect. Whenever there’s acid in the system, the next compressor […]

Read more

This tech tip was written by Tim De Stasio. He originally published it on his website, which you can visit HERE. Thanks, Tim! In March of 2024, I set out to better understand the cost of ownership and return on investment for two dehumidification strategies: a dedicated dehumidifier versus using electric reheat dehumidification from my […]

Read more

When we think of HVAC system components, the big four come to mind: evaporator, compressor, condenser, and metering device. However, there are several accessories that keep the HVAC system working as intended, and the filter-drier is one we cannot ignore. Filter-driers protect HVAC/R systems by removing moisture, acids, and debris from refrigerant. In typical residential […]

Read more

We’ve talked about compression ratio a lot over the years. Compression ratio is the number you get when you divide the absolute head pressure (PSIG + 14.7) by the absolute suction pressure (PSIG + 14.7). It measures the efficiency of a compressor, and lower numbers indicate that the compressor is moving more refrigerant while consuming […]

Read more

If you own your HVAC company or are involved in management, you may have realized that our industry is currently facing a shortage of new A2L refrigerants, particularly R-454B and R-32. Our own company has faced limited availability and long lead times, mainly due to supply chain disruptions and the increased demand now that our […]

Read moreVideos:

Podcasts:

In this episode of the HVAC School podcast, Bryan welcomes back Jim to discuss the groundbreaking SureSwitch contactor technology from Copeland. This isn't just another incremental improvement – it's a complete reimagining of how contactors should work in modern HVAC systems. Jim brings his expertise and even demonstrates the technology with a special cutaway […]

Read more

In this short podcast episode, Bryan goes through the process of testing and replacing a run capacitor. Run capacitors provide continuous phase-shifted current to the start winding, allowing the motor to run in the right direction and with the appropriate amount of torque. These capacitors are needed in most of the single-phase PSC motors […]

Read more

In this comprehensive episode of the HVAC podcast, Bryan hosts an in-depth discussion about dehumidification technologies with two industry experts: David Schurk, National Sales Manager for Innovative Air Technologies, and Nikki Krueger from Santa Fe Products. The conversation explores the fundamental differences between compression refrigeration dehumidification and solid desiccant systems, providing valuable insights for […]

Read more

In this short podcast episode, Bryan talks about learning styles and gives some tips for “learning better” and getting more out of continuing education opportunities. The first step to getting more out of educational opportunities is to know your learning style. There are three main styles: visual, kinesthetic (hands-on), and auditory. Most tradespeople will […]

Read more

Sharon Goepferich from Cool Air Products joins the podcast to discuss cutting-edge capacitor technology and innovative HVAC solutions in an introduction to the Sigma capacitor. Sharon brings a decade of industry experience, having worked extensively with capacitors and HVAC components while traveling across the country to educate technicians and contractors. The conversation begins with […]

Read more

In this insightful episode of the HVAC School podcast, host Bryan sits down with Jennifer Butsch, Director of Regulatory Affairs at Copeland, to discuss the rapidly evolving regulatory environment affecting the HVAC industry. With eight years of experience at Copeland and a background spanning codes, standards, and regulatory affairs, Jennifer provides a unique perspective […]

Read more

In this short podcast episode, Bryan walks through some common thermostatic expansion valve (TXV) troubleshooting scenarios. Many of the same principles apply to troubleshooting electronic expansion valves (EEVs). These dynamic metering devices maintain a constant superheat. Troubleshooting does NOT start and end with the TXV. First, you need to inspect components (especially filters, ductwork, […]

Read more

In this episode of the HVAC School podcast, host Bryan Orr and guest Ty Branaman have an in-depth, hands-on conversation about the philosophy, structure, and impact of GRIT Camps—workshops designed to introduce kids to the trades through immersive, practical experiences. The episode opens with reflections on a recent successful GRIT Camp in New Jersey, […]

Read more

In this short podcast episode, Bryan talks about band-aids, hacks, and ethics. He explores ethical “band-aid” solutions and how to charge for them. He also covers the difference between patching up equipment ethically and unethical repairs. Temporary fixes and ugly permanent fixes fall into the ethical gray area for a lot of people, especially […]

Read more