BACK

Fancy Refrigerant Words

Fancy Refrigerant Words

Changing Refrigerants and Why it Matters to You

Changing Refrigerants and Why it Matters to You

EPA Section 608 Changes Every Tech and Contractor Needs to Know (Podcast)

EPA Section 608 Changes Every Tech and Contractor Needs to Know (Podcast)

#hcfc

Tech Tips:

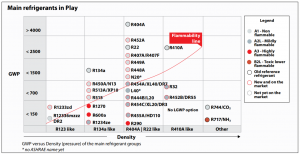

The HVAC industry uses all sorts of fancy words to classify refrigerant. As such, there are all sorts of complicated refrigerant acronyms: HFC, HCFC, CFC. Let's also not forget the mythical zeotropic, azeotropic, and near-azeotropic descriptors. Let's simplify those. (Though if you want to go back to the basics first, check out this article on […]

Read more

Graphic Courtesy of Danfoss On 8/8/17, the United States court of appeals struck down an EPA phaseout of HFC refrigerants under the Clean Air Act on the basis that the Clean Air Act only gave the EPA the right to regulate ozone-depleting substances. However, many of us figured that the decision was likely to be […]

Read morePodcasts:

In this episode of the podcast, Jeremy Arling from the EPA comes on and answers some common questions about the new rule changes that affect recovery, leak repair, recordkeeping, and evacuation on HVAC and refrigeration systems. EPA 608 rules regulate the actions that technicians must take when it comes to refrigerants and the atmosphere, such […]

Read more