BACK

Work Vehicle Entropy

Work Vehicle Entropy

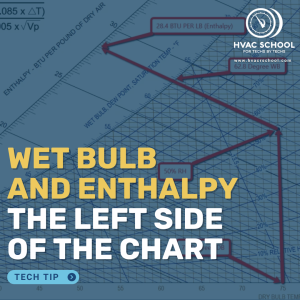

Wet Bulb and Enthalpy – The Left Side of the Chart

Wet Bulb and Enthalpy – The Left Side of the Chart

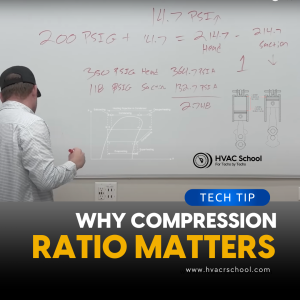

Why Compression Ratio Matters

Why Compression Ratio Matters

Where Do I Measure Delta T?

Where Do I Measure Delta T?

Adiabatic Cooling, Blower Settings, and Why You Care

Adiabatic Cooling, Blower Settings, and Why You Care

What is Enthalpy?

What is Enthalpy?

Pressure / Enthalpy Diagram Example

Pressure / Enthalpy Diagram Example

A Bit of Adiabatic Air Science For Techs – FB Live Video

A Bit of Adiabatic Air Science For Techs – FB Live Video

Psychrometrics Without Tears

Psychrometrics Without Tears

#enthalpy

Tech Tips:

Have you ever noticed that the more you're required to speed up to get all your work done in a day, the more the cleanliness of your work vehicle suffers? Some techs won't clean their vans, no matter how slow or busy the schedule gets, but most of us prefer a clean and organized vehicle. […]

Read more

It's incredibly useful to understand wet-bulb temperature and air enthalpy when calculating actual system capacity and human comfort. Dry-bulb temperature is a reading of the average molecular velocity of dry air. However, it does not account for the actual heat content of the air or the evaporative cooling effect of the air. When air is […]

Read more

In HVAC/R, we are in the business of moving BTUs of heat, and we move BTUs via pounds of refrigerant. The more pounds we move, the more BTUs we move. In a single-stage HVAC/R compressor, the compression chamber maintains the same volume no matter the compression ratio. The thing that changes is the number of […]

Read more

Over time, I’ve seen people use just about every type of temperature-measuring device in just about every location imaginable. From drilling tiny holes into rooftop unit panels to sticking a K-type wire into a piece of flex duct (I don’t remember why), I’ve done it all. Coming up through the trade, I’ve been TOLD to […]

Read more

Just so you don't get bored and quit reading, let's get straight to the point. When the blower runs for more than a few minutes after the system has cycled off in cool mode, the air may continue to be “cooler” (lower sensible temperature) coming out of the supply. However, the heat content of the […]

Read more

Enthalpy is easy. It's just a state function that depends only on the prevailing equilibrium state identified by the system's internal energy, pressure, and volume. It is an extensive quantity. Simple. Like most things, the scientific definition is as clear as mud. In HVAC/R, we use enthalpy measurement to come up with the total heat […]

Read more

This article was written by my buddy and Canadian Supertech Tim Tanguay. Thanks, Tim! This P/E chart shows R410a at 100°F saturated condensing temp, 10°F SC, 40°F saturated suction temp, 20°F SH at the compressor. The green highlighted thumb shape is the saturation zone. Everything that occurs in the saturation zone is a latent (change […]

Read more

In this video Bryan talks about Heat (Enthalpy) Adiabatic cooling Latent and Sensible heat Evaporative Cooling Humidity Blower Off Delay

Read moreEvents:

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more