BACK

Fresh Air in Commercial Buildings: Economizer Sensors and Settings

Fresh Air in Commercial Buildings: Economizer Sensors and Settings

5 Things to Consider When Maintaining a Commercial Package Unit

5 Things to Consider When Maintaining a Commercial Package Unit

Ain’t No Fooling With Free Cooling (Tales of the Economizer)

Ain’t No Fooling With Free Cooling (Tales of the Economizer)

HVAC Fire Safety Systems in Restaurants

HVAC Fire Safety Systems in Restaurants

So You Want to Service VRF?

So You Want to Service VRF?

#commercial hvac

Tech Tips:

This tech tip is based on a presentation by Joey Henderson, a veteran symposium speaker and excellent HVAC educator. You can learn more about Joey and the work he does at joejoehvac.com and his YouTube channel HERE. Simply put, indoor air is often nasty. People cough up and exhale germs, and cracks in the envelope […]

Read more

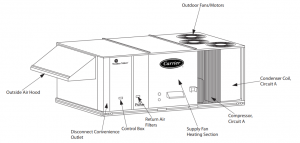

If you are primarily a residential technician working on equipment under 5 tons, there are many similarities between the systems you are used to and 5-20 ton rooftop units common to the light commercial market. There are MANY additional things to consider on larger equipment, and here are just a few. Wash Fresh Air Filters […]

Read more

This article was written by Gary McCreadie from “HVAC know it all.” You can learn more about Gary and his tips and growing community on Facebook and LinkedIn. What is an economizer? Simply put, it is a mechanical device designed to reduce energy consumption, whether it be fuel, electricity, or other. According to Wikipedia, the first […]

Read more

This article was written by Christopher Stephens. He is a commercial HVAC/R service manager in the greater Los Angeles area. Thanks, Chris. Let’s start by covering the three elements needed for a fire: fuel, air, and heat (spark). With those three elements in the right condition, you can start a fire. So, if we reduce […]

Read moreVideos:

Events:

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more