Videos

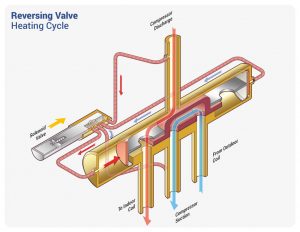

If you don’t have a gas furnace or fireplace in your home, your unit’s reversing valve is probably your best friend during the winter months. As their name suggests, reversing valves reverse the refrigerant flow to send the hot, compressed vapor to the indoor coil instead of the outdoor coil. The system releases heat into […]

Read more

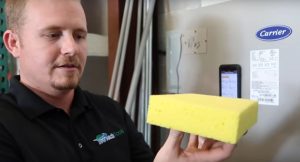

When you first start checking your supply air with a thermo-hygrometer, you may notice that the relative humidity is REALLY HIGH. Often, the RH in a supply duct will be between 85% and 96% relative humidity on a system that is functioning as designed. The reason for this is fairly simple: In order for dehumidification […]

Read more

Capacitors are traditionally tested with a capacitance meter (commonly found as a function within a multimeter), with the component taken entirely out of the circuit. “Bench testing,” as this method is referred to, is hands-down the safest method of checking capacitance in microfarads. All other methods require the capacitor to be wired into the circuit […]

Read more

I was about 13 years old the first time I bent EMT with my uncle. We were doing a renovation at a church; watching him bend EMT and then getting to do it MYSELF was a truly religious experience. There are a few things in the trade where workmanship really comes into play, such as […]

Read more

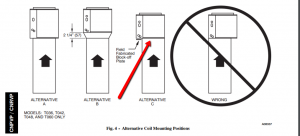

On occasion you will either find a furnace or be tasked with installing a furnace where the coil overlaps the edge of the furnace because the coil is wider. In the case of a Carrier CNPVP coil you need to ensure that you align the coil according to manufactures specs or you risk cutting off […]

Read more

I hear many techs complain about the finicky and ineffective nature of electronic leak detection. So much so that some claim that it is a waste of time altogether. We recently located a leak inside the fins of a ductless evaporator coil—pinpointed to an exact spot—using an electronic leak detector. For demonstration purposes, we took […]

Read more

Cleaning ductless systems is critical… and a pain.. Rather than just telling you how we do it let me show you some of the key points. This video demonstrates cleaning and testing a ductless system including pulling the blower wheel and washing the evaporator with a bib kit. I also wrote a process for […]

Read more

As a technician gains skill they will learn that regularly testing your tools is a huge part of success. It isn't long in the field before techs find out that just because a meter or gauge gives a particular reading it doesn't ALWAYS mean it is correct. Vacuum is one of these areas. Everything in an […]

Read more

Evacuation Start to finish with some of the best evacuation practices. Click below to see the video. –Bryan

Read more